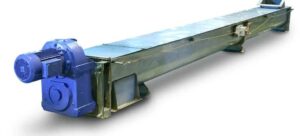

KWS Shafted Screw Conveyors are available in many configurations. Shafted Screw Conveyors are designed based on industry standards and are modular in construction providing flexibility for a variety of applications.

Advantages of Using Shafted Screw Conveyors

- Ideal For Handling Dry To Semi-Fluid Materials – Free-Flowing To Sluggish

- Cost-Effective When Compared To Other Conveying Devices Such As Belt, Pneumatic Or Aero-Mechanical Conveyors

- Efficiently Distributes Bulk Materials To Various Locations Using Multiple Inlet And Discharge Points

- Totally Enclosed For Corrosive Or Hazardous Requirements

Vertical screw conveyors are a very efficient method for elevating a variety of bulk materials at very steep inclines or completely vertical. The compact design allows for the vertical screw conveyor to fit into almost any plant layout. With a minimum number of moving parts, the vertical screw conveyor is a cost-effective and dependable component of any bulk material handling process.

Advantages of Using Vertical Screw Conveyors

- Ideal For Handling Dry To Semi-Fluid Materials – Free-Flowing To Sluggish

- Capacities Available Up To 6,000 Cubic Feet Per Hour

- Ability To Elevate Bulk Materials Up To 30-Feet Without Use Of Internal Bearings

- Totally Enclosed Design For Dust And Vapor-Tight Requirements

Bulk materials discharged from centrifuges, filter presses or mixers can easily be metered or conveyed using a shaftless screw conveyor. Our shaftless design provides a non-clogging conveying surface that allows difficult-to-convey materials to become easy-to-convey. The perfect solution for handling bulk materials with high moisture content is the KWS Shaftless Screw Conveyor.

Advantages of Using Shaftless Screw Conveyors

- Ideal For Handling Sticky And Sluggish Bulk Materials

- Improved Conveying Efficiency When Compared To Other Types Of Conveyors

- Allows Greater Flexibility For Plant Layout Due To Configurations Available

- Internal Bearings Are Eliminated